0102030405

CNC800B2 CNC drilling and milling machine for aluminum profiles

Application

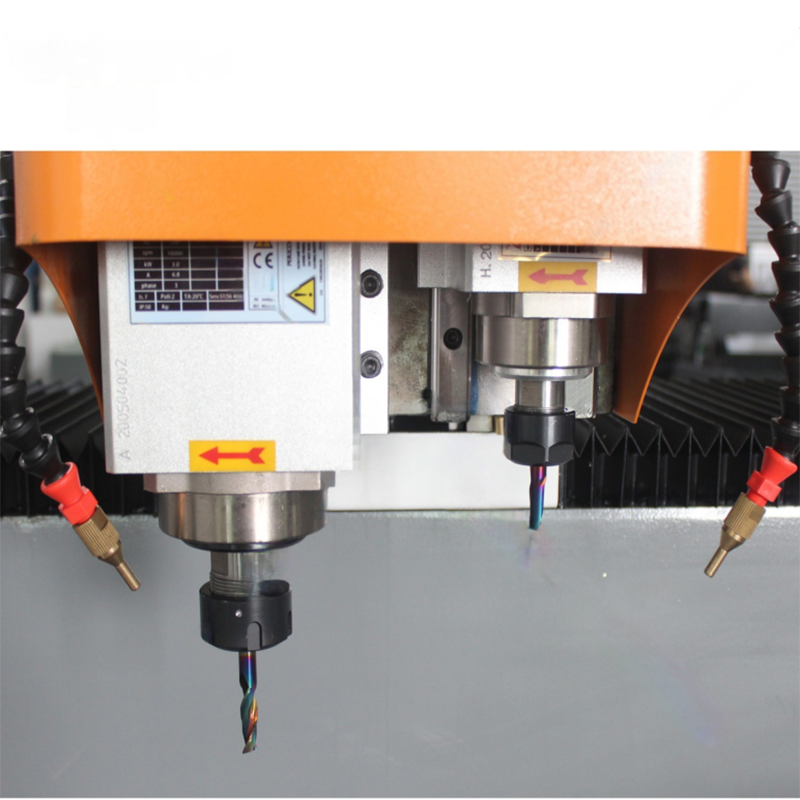

1.The CNC 800B2Aaluminum profile CNC drilling and milling integrated machine is an efficient and precise processing equipment, suitable for drilling, milling grooves, circular holes, irregular holes, locking holes and other processes of various aluminum alloy profiles. Its characteristic is that it can process three sides of the profile simultaneously after one clamping, greatly improving processing efficiency and accuracy. The X, Y, and Z axes of the motor base are guided by imported precision linear guides, ensuring the stability and accuracy of the equipment during high-speed operation. The operating system adopts Taiwan Baoyuan CNC system, which has a friendly interface, simple operation, and can achieve high-precision machining requirements.

2.In the industry of building doors, windows, and curtain walls, the CNC 800B2 aluminum profile CNC drilling and milling integrated machine has performed excellently. It can complete the multi sided processing of profiles in one clamping process, making the processing of doors, windows, and curtain walls more efficient and accurate, ensuring the simplicity of operation and high precision of processing, greatly reducing manual operation errors, and improving production efficiency and finished product quality. For manufacturers of building doors, windows, and curtain walls, this equipment is undoubtedly an ideal choice to enhance production capacity and product competitiveness.

3.In the field of industrial aluminum profile processing, the CNC 800B2 aluminum profile CNC drilling and milling integrated machine has also demonstrated its excellent performance. The equipment can handle various complex processing tasks, such as drilling, milling grooves, irregular holes, and locking holes, to meet the diverse processing needs of industrial aluminum profiles. The combination of high-precision guide rails and Taiwan Baoyuan CNC system enables the equipment to maintain high precision and stability even during high-speed operation. Whether it is large-scale production or customized processing, this equipment can provide reliable solutions to help industrial aluminum profile processing enterprises improve production efficiency and product quality, and meet the diverse needs of the market.

| Product model | Product technical parameters | |||

| CNC800B2 aluminum profile CNC drilling and milling machine | Lateral travel (X-axis travel) | 800 | ||

| Longitudinal travel (Y-axis travel) | 350 | |||

| Vertical travel (Z-axis travel) | 300 | |||

| X-axis operating speed | 0-30m/min | |||

| Y/Z axis operating speed | 0-30m/min | |||

| Milling cutter/drill cutter spindle speed | 18000R/min | |||

| Mill/drill spindle power | 3.5KW/3.5KW | |||

| Working position of table | 0°、+90° | |||

| System | Taiwan Baoyuan system | |||

| Cutter/drill cutter chuck | ER25-φ8/ER25-φ8 | |||

| Cutter/drill cutter chuck | 0.6-0.8mpa | |||

| Working power supply | 380V+ neutral line, three-phase 5-line 50HZ | |||

| Total machine power | 10KW | |||

| Processing range (width, height and length) | 100×100×800 | |||

| Tool cooling mode | Automatic spray cooling | |||

| Main engine dimensions | 1400×1350×1900 | |||